Numerical modelling of welding - Lindgren

Welding simulation (computational welding mechanics) dates back to the 1970s

Model:

Simulation:

Validation:

Calibration:

Prediction:

Verification:

Qualification:

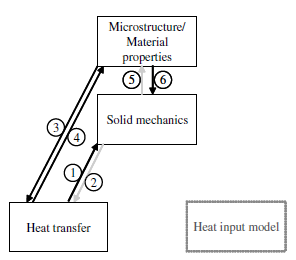

Couplings

- Thermal dilatation drives deformation

- Deformation generates small amount of heat

- Latent heat due to phase changes and thermal properties depend on microstructure and temperature

- Temperature drives microstructure changes

- Deformation affects microstructure changes

- Mechanical properties depends on microstructure

Fluid flow is not accounted for

High temperature region is approximated by a soft solid in mechanical analysis, a given heat input in thermal analysis, and sometimes a high conductivity for imitating convective heat transfer in the weld puddle

The most common approach is to split thermal analysis followed by mechanical analysis. This is a conditional stable.

There exists thermo-metallurgical-mechanical (TMM) analysis which is unconditional stable.

Reference frames

Updated Lagrangian

Eulerian

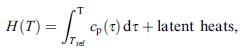

Thermal analysis

Energy relation from heat conduction

dst

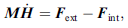

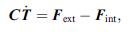

Mechanical analysis

Scope of analysis and accuracy

Questions that may be scope of welding simulation. Sorted based on modellling complexity:

- What are the residual stresses

- What are the final deformations

- What are the transient stresses and deformations

- What is the microstructure of the weld and HAZ

- What causes hot cracking

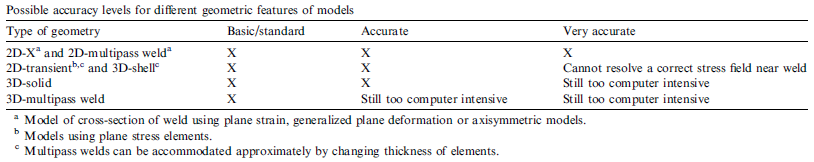

Accuracy levels:

- Reduced accuracy levels: for evaluations at preliminary design stages

- Basic simulation: answer question 1 and 2

- Standard simulation: answer questions 1-3

- Accurate simulation: answer 1-4

- Very accurate simulation: answer 1-5

Level 1, 2 and 3 are well-established.

Geometric models

Heat input models

Analytical splutions mostly use Rosenthal's. Not appropriate for numerical in vicinity of weld area.

The Gaussian heat source model is appropriate for accurate analysis, needs at least four quadratic elements.

Material models

Applications

- Effect of residual stresses on intergranular stress corrosion cracking

- Calculating limiting pressure for welding a pipe with internal pressure

- Finding residual stress for fatigue analysis

- Design low stress low distortion welding techniques

- Reducing risk for cracking

- Predict distrotion due to welding

Improvement of modelling in CWM

Mostly concerned with heat input and material model aspects.

Created with the Personal Edition of HelpNDoc: Easily create PDF Help documents